Batteries, Inverter, Distribution Panel, and Wiring:

|

I bought this 1500 watt Coleman inverter to power a few things like the cappuccino maker and the microwave. I had intended to power the fridge and electronics from separate smaller inverters. However, before I started wiring I wanted to get some real efficiency numbers. I rigged up a shunt to measure amps on the 12 volt side and tried the big Coleman, a 350 watt Whistler inverter and a computer UPS with several different loads. I did find a difference in current draw, but it was smaller then I thought it would be. Furthermore, all of the loads performed markedly better on the Coleman. Both the fan and the light bulb buzzed slightly on all sources, but they buzzed the least on the Coleman. |

|

|

Surprisingly the computer UPS was the dirtiest. Both the light bulb and the fan buzzed a lot on the UPS. The fan would not even run at full speed unless the resistive load of the light bulb was in parallel with it. The Whistler worked better then the UPS, but the Coleman ran the fan quietly and with no speed change. So, I think I will keep it simple and dispense with the other inverters. I will, however, use a UPS or two in line to carry the load of certain equipment during transfer to and from shore power, this to prevent the annoying flashing "12:00". |

|

Data: No Load 150w

bulb Fan Fan&Bulb Router

Coleman 1500 .2-.3 13.7

6.4 18.4 33.6

Whistler 350 .2

12.3 4.6 17.1 n/a

UPS

.4 12.5

4.6 18.3 n/a

|

These EPIs from the dump fit quite nicely over the windshield, they sound nice too. The Receiver came from the road-side trash and just needed a bit of contact cleaner. It runs nicely from the Coleman inverter. |

|

|

You want the house batteries as close as possible to the alternator. Looks like my two golf cart batteries will just fit in front of the air cleaner. |

|

|

I made a hold down bracket for the batteries from bed frame angle iron. Every week I bring home at least one bed frame from the dump, I use them for everything. They seem to come in 1" and 1 1/4" sizes. Be sure to anneal them before drilling, if you don't you'll use up drills very quickly. |

|

|

The battery shelf is cantilevered out from the frame rail so I installed this rod to help support the outer edge. Since this rod connects body to frame, I put a pair of rubber bushings at the shelf. |

|

|

Batteries in, it's a very tight fit, the air cleaner has to be removed to get the batteries in and out. |

|

|

None of the battery isolators at my local RV shop Timbucktu were large enough to handle my 150 Amp alternator so I bought this switch (250 Amps) without being quite sure how I would use it. The cables are from a friend who works at Cisco, they were cut just a little too short for the rack they were going into and my friend rescued them from the dumpster for me. They've been sitting in my garage for more then five years. The third lug will connect to a battery charger. |

|

|

Mounted switch. |

|

|

The switch will actually work out rather well.

|

|

| After a lot of thought I decided to layout the

electrical panels on a couple of boards like one might do in a house. I figured

out where in the engine compartment I had enough room and cut and primed a couple of

pieces of 3/4" plywood. |

|

| Here is the completed DC board. The wire

feeding the inverter is 4/6 SOA cable, I have combined the red and white and

black and green conductors to get the equivalent current carrying capacity of AWG 4

wire, which is what the inverter called for. The fuse block is rated at 100 amps

in so the 6 AWG was sufficient. |

|

| Here is the completed AC board. The panel is a 2

bearer box I found in a dumpster near work and the breakers are a 2-gang 20 AMP GFI

breaker I bought by accident a couple of years ago thinking it was a single gang.

Sharp eyes will not that the quad on the right contains a switched outlet, this will be

for the battery charger the output of which will connect to the big 250 battery

switch. |

|

| Here's another view of the batter hold down I made

from the old bed frames. |

|

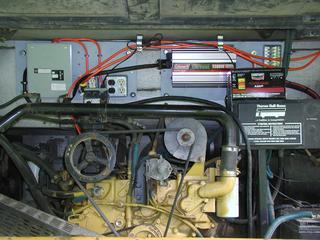

| The completed boards mounted in the engine

compartment. I did think about heat from the engine effecting the inverter.

However, when the engine is running the fan draw a stiff wind through the grill.

It's only just after stopping the engine that I am likely to get high temps at the top

of the engine compartment. The inverter does have it's own fan as well.

We'll see how it works out. You can see in the picture that the AC box is plugged into the inverter with a 30 - 20 AMP adapter. This is "on internal power" mode for travel and camping without external AC. When AC is available I'll simply plug into the 20 foot 10/3 SOA extension cord I made. |

|

| Here's the installed battery charger. It's

plugged into the switched outlet on the AC side and wired into the 250 amp battery

switch on the DC side. I had originally purchased a "Smart" charger to install

here. However, when I tried it out I found that the RFI from the switching power

supply interfered with radio reception to an unacceptable degree. The "Smart"

charger now lives in my garage and this old transformer charger will travel with the

bus. |

|

| The interior wiring will be mostly contained with in the wiring channel above the windows. There is plenty of room in either side for several cables. Wire will be brought down the side of the bus in wireways like this product from Home Depot. This circuit will be for small kitchen appliances. |  |

| I've opted for brown bakelite switches and outlets

with solid brass plates to give things the early 20th century look I'm going

for. |

|